ATT Brake Motor Series are made to efficiently perform braking duties. Our team can fully customize these brake motors according to the customer’s different requirements.

Our selection of brake motors can also be used in marine industries for winches and other purposes.The electro-magnetic disc brake is powered, by either DC current through a rectifier located in terminal box or three phase AC current. When the brake coil is de-energised, the brake is actuated by spring pressure. The axial movement of the brake disc performs a dual braking action against the moving electromagnet and the motor shield, without pressure or impact being transmitted to the bearings.

| Item |

Standard Specifications |

| Type of Motor |

Squirrel Cage Cast Iron / Aluminium Induction Brake Motor |

| Design Standard |

IEC 60034-1 |

| Framesize |

80-315L |

| Voltage and Frequency |

Standard stock available are:220-240/380-415V/50Hz for 2.2 KW & below

380-415/660-720V/50Hz for 3KW & above

Other voltages & frequency such as 200V, 346V, 440V & 60Hz can be supplied on request |

| Power Conditions |

± 5% of rated voltage; ± 1% frequency and ± 1% phase unbalance |

| Efficiency Standard |

IE1 / IE2 / IE3 (IEC 60034-30-1) |

| Cooling Method |

Self external fan, surface cooling (IC 411); No external ventilation (IC 410) |

| Method of Starting |

Full voltage direct on line starting or star-delta starting |

| Insulation & Temperature Rise Class |

Class F insulation and Class B temperature rise |

| Degree of Protection |

IP55 |

| Rotor Winding |

Squirrel cage, aluminium conductor with end-ring and wafter blades integrally cast |

| Environmental Conditions |

Place: Non-hazardous, shadedAmbient temperature: -20°C to 40°C

Relative humidity: Less than 90% relative humidity (non-condensation)

Altitude: Up to 1,000 metres above sea level |

| Direction of Rotation |

Standard motors are suitable for operation in either direction of rotation of shaft.Direction of rotation can be reversed by interchanging any two of the power lines. |

| Test Procedure |

IEC and full voltage measuring starting operation |

| Fan Cover |

Pressed steel |

| Shaft |

Carbon Steel, round shaft with key |

| Bearing |

Grease pre-packed shielded ball bearing |

| Lubrication |

Lithium-base grease (Shell Alvania R3) |

| Painting |

Phenolic rust-proof base plus lacquer surface finish. Painting in ATT Blue |

| Ground Terminal |

NE set inside the terminal box |

| Other Options Available (Contact ATT to inquire for other options) |

| VSD Driven |

Inverter duty motor suitable for VSD operation |

| Heaters |

Space heaters (110V/220V/1ph) or winding heaters available on request |

| Thermal Protection |

PTC thermistor 150°C; Bearing & Winding RTD |

| Brake Accessories |

Manual hand release / Wheel release / Bolt release |

| Rectifier |

Can operate within 10% voltage variations; compact, can be installed in main T-Box |

| Shaft |

Double ended shaft; Special shaft |

| Insulation Class |

Class H |

| Degree of Protection |

Up to IP66 |

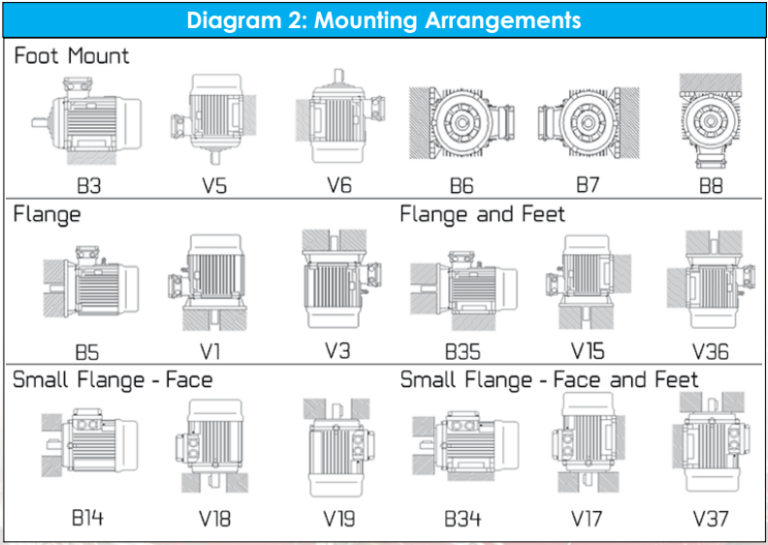

The table below contains the various types of mounting available for Brake Motor Series. If you are unable to find the dimensions to the mounting you prefer, please contact us for the outlining dimensions.